My motors came today.

Yikes … never had such small motors, hope they are powerful enough ![]()

lol… That’s the size of motors I started with! I have gone smaller for my tiny whoops.

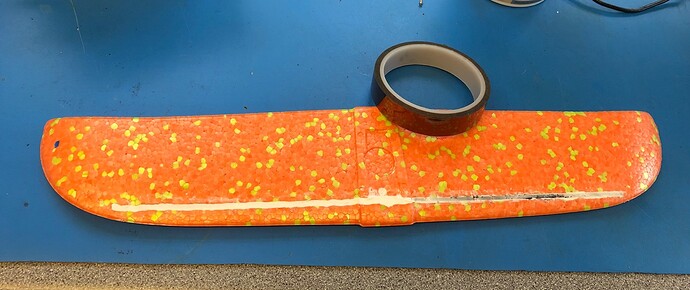

Been away for a few days but just managed to get the carbon spar fitted to the main wing.

To keep the lower wing surface smooth I’ve filled in with foam filler.

When dry a layer of Kapton tape, being the sameish sort of colour should keep it looking tidy.

Next is the spar in the fuselage and make the elevator assembly ![]()

What is this exactly? I’ve used this in the past…

It’s actually the exact same stuff as this:

or there’s this:

https://www.amazon.co.uk/Foam-Tac-Foam-Filler-Clear/dp/B01HO0UQHU/ref=asc_df_B01HO0UQHU/?tag=googshopuk-21&linkCode=df0&hvadid=258634840980&hvpos=&hvnetw=g&hvrand=7911098526892329432&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=1006627&hvtargid=pla-432242721003&psc=1&th=1&psc=1

which I do wonder if it’s actually the same stuff again… But I’ve not tried this, whereas I have tried both of the first two.

Hi Rich

Yes, agree ![]()

I bought the Foam Putty as well

When I can’t remember where I put it, often, I use the cheap fine filler paste as well

Not quite sure they are the same product, I do think the Foam Putty is lighter and more open-cell but consider how little is used I reckon it doesn’t give a damn which one

![]()

![]()

Yeah, that filler I posted is not like normal wall filler. It has the same foamy light open-cell feel that the woodland scenics stuff has, just at a fraction of the price. I’ve used loads of it.

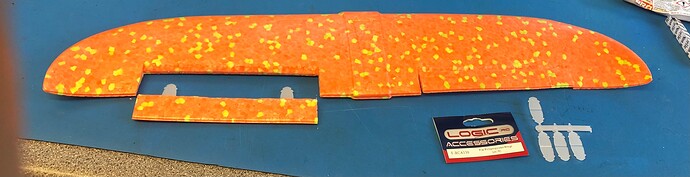

Todays progress…

Fitted carbon spar to underside of fuselage for rigidity

Cut new ailerons, these are larger at 135x20mm previously 110x13mm

Fitted them with hinge pieces, I usually use Blenderm tape for strengthening the usual foam hinges but as these are cut new I think it’s best to use ‘proper’ hinges.

Made a bit of an error cutting the chamfers to give space for movement. I did this on the wing side but it would have been better on the aileron side.

Link to video for fitting hinges below.

These ailerons are a bit flimsy, so I’m going to have to fit yet another spar. As they are so thin instead of recessing it I think I’ll just glue a flat one on the top surface.

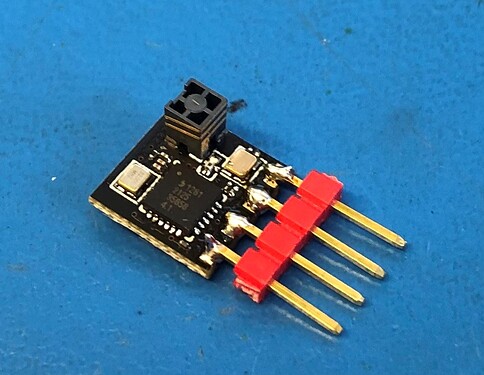

My Zorro transmitter, the ELRS version, came over the weekend so I’ve been able to flash the latest firmware to the tiny EP2 receiver along with bind code and preferences. I did the TX by USB cable and the RX with it’s own WiFi. All worked great ![]() …God… it’s tiny…

…God… it’s tiny…

Hmmm… polyproylene… I can 3d print in that.

After a semi successful test flight on Sunday, I have made a few adjustments to the elevon.

(The plane was climbing with increasing throttle. The cofg seems ok, slightly nose heavy.)

I’ve hinged it with glue at this point instead of the bottom, and I have adjusted my servo offset for (hopefully) a level flight when the pitch stick is centred. If not, I can adjust it in the tx.

Does the motor thrust line sit below the level of the wings? If so, that’ll cause pitch up on high throttle as the motor tries to pull the bottom of the plane underneath the wings like a pendulum. Either a tiny bit of down angle on the motor can help, or often easier to add a bit of throttle mix to the elevator in your TX settings so the amount of down elevator you get is proportional to how many beans you’re giving it. Adjusting the servo position mechanically is a good start but will often only give you level flight at one particular throttle position.

(apologies if I’m preaching to the converted here - just sharing what I’ve picked up over the past couple years of building DIY stuff like this)

I’m still waiting for parts to arrive, anyway as a chuck glider mine has an stabiliser leading edge at a negative angle to the thrust line which is normal for a nose up when chucked hard. I know I’ll have to adjust the thrust line by a small wedge under the stabiliser’s leading edge…in hope…lol

I can’t commit to changes to the glider until I have the motors and battery, I have though decided not to cut out the ailerons and elevator but instead to 3D print full length aileron and elevator. The hope is to increase the wing cord and thus wing area and hopefully more functionality through a wider flight envelope. I’m yet to decide on the method of hinging, tape is at the foremost in my mind.

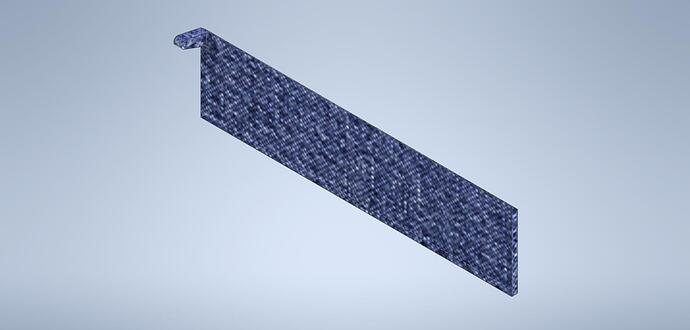

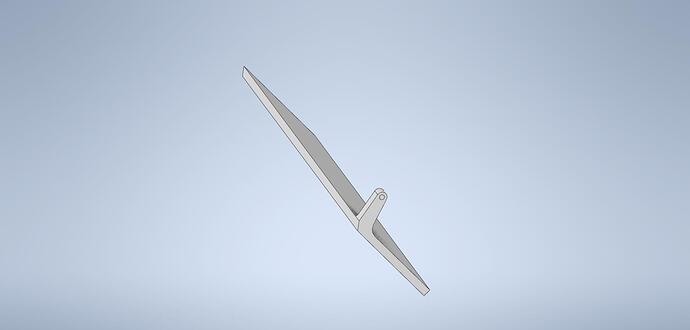

Here’s what I’m thinking of subject to change though to full length. Elevator

The plan is to print vertically with the horn on the table which will allow me to use 2 different print profiles. The first from the table to the end of the horn vertically at 100% infill and then then rest at say 25%…

That is interesting. Should make it possible to repeat and move to other planes etc.

A chap on the fb group was going on about this. But i couldn’t see anything on mine to say it was like that. He went quiet and didn’t help much. Any chance of more detail? Photos? Diagrams?

Yes, I’ll post as soon as I get it all redrawn as the tip has a curve to it, I may actually just draw the entire wing and mock it up in assembly as that’s when it really comes together visually before committing to print.

All advice is welcome. I test, change things and retest. Then learn

Dammit, I’ve going to have to get one of my still-boxed ones and build something aren’t I, you’ve all inspired me. I’m tempted to try a fully articulating wing instead of ailerons…

Skip to 6:00…

I wonder what would happen if you built this twisting wing design, with twin motors… ![]()

where did you get the horn from ??? ![]()

instead to 3D print full length aileron

I briefly thought of this, however on the donor glider the trailing wing edge is not that strong and not sure it would support an aileron.

If I find that mine just dont have enough air authority then I’m think I could strengthen it and add a balsa wood aileron ![]()

I’m tempted to try a fully articulating wing instead of ailerons…

That’s a coincidence, I was watching this with my breakfast this morning ![]()

where did you get the horn from ???

I found it on the floor in the shed ![]()

Ah sorry, I get it! Page 3

Ah sorry, I get it! Page 3

???

It was a serious question ![]()

![]()